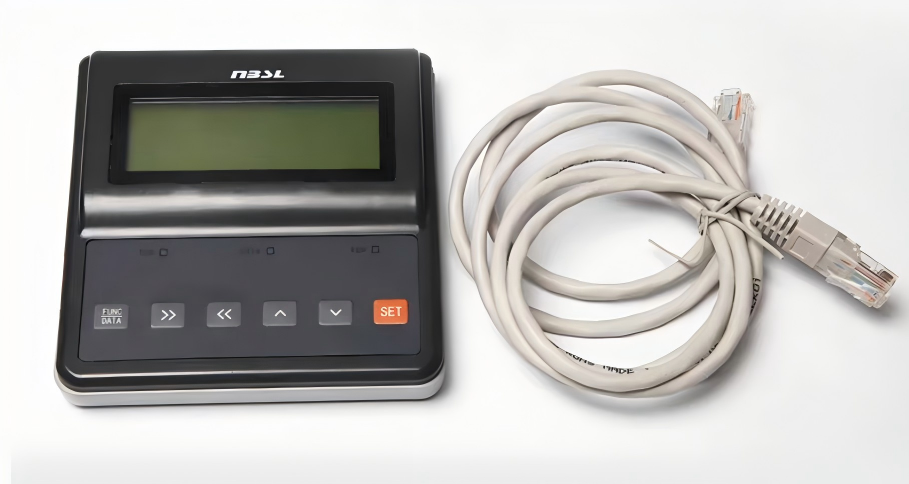

Elevator door motor inverter controller NSFC01-02 operation debugger

An elevator door operation debugger, often called a service tool, operator debugger, or handheld server, is a specialized diagnostic device used by technicians to configure, test, and troubleshoot elevator door controllers.

Core Functions—Modern door systems use closed-loop controllers that require specific parameters for safe operation.

Debuggers allow technicians to:

1、Self-Learning: Calibrate door width and travel limits by initiating a “learning” cycle where the door opens and closes to store physical distances.

2、Curve Adjustment: Modify the opening and closing curves, including acceleration/deceleration points, creeping speeds, and holding torque.

3、Fault Diagnostics: View error codes (e.g., door lock monitoring issues) and clear fault history after repairs.

4、Mode Switching: Toggle between manual mode (for testing) and elevator operation mode (where the main controller takes over).

What it does:

1、Reads Faults: Connects to the elevator controller (motherboard) to display error codes related to door operation.

2、Adjusts Parameters: Allows technicians to fine-tune door motor settings, timing, and speed curves.

3、Manual Control: Enables manual opening/closing and jogging of doors for testing.

4、Monitors Status: Provides real-time data on door position, contact status, and system health.

5、Clears Faults: Resets error logs after repairs.

Types & Examples:

1、TT Server (GAA21750AK3): A popular, often blue, universal tool for many brands, sometimes requiring unlocking.

2、Pt MC2: A robust tool for Thyssen elevators, handling harsh conditions.

3、Brand-Specific Tools: Some manufacturers (Otis, Monarch, Canny, Xizi) have their own servers or require specific decoders/debuggers.

Why it’s used:

1、Diagnoses complex door malfunctions not easily seen by simple inspection.

2、Ensures doors meet safety standards (e.g., monitoring door lock circuits).

3、Optimizes performance for smoother, quieter, and faster operation.

How it works (Simplified):

1、Technician connects the debugger to the elevator’s control board.

2、The debugger communicates with the system, often requiring a password or decoder for certain boards.

3、Technician uses the interface to check parameters (like those in parameter P0.06 for terminal control) or test functions.

4、Adjustments are made, and faults are cleared after repairs are complete.

Post time: Jan-16-2026