In our daily lives, passenger elevators and freight elevators are two common types of elevators. Many people may simply think that freight elevators are used to load goods and passenger elevators are used to transport passengers, but they overlook the deeper differences between them!

Basic differences between freight elevators and passenger elevators

1. Design Purpose

Freight elevators are primarily used for transporting goods, featuring a larger cabin space and higher load capacity. Common load capacities are 2000KG, 3000KG, 5000KG, or even heavier, to meet diverse cargo transportation needs.

Passenger elevators are primarily used to transport passengers, with a greater emphasis on passenger comfort and safety. Their cabin dimensions are relatively smaller, and load capacities generally range from 630kg to 1600kg. They are designed according to different usage locations and passenger flow to adapt to various passenger transportation needs.

2. Running Speed

Freight elevators operate at a relatively slow speed, typically not exceeding 1 m/s, to ensure the stability and safety of goods during transportation.

Passenger elevators are relatively fast. In mid- to high-rise residential buildings and office buildings, passenger elevators can generally reach speeds of 1.5 m/s to 2.5 m/s, or even higher. This is primarily to improve personnel efficiency, reduce passenger waiting time, and meet people’s needs for rapid travel.

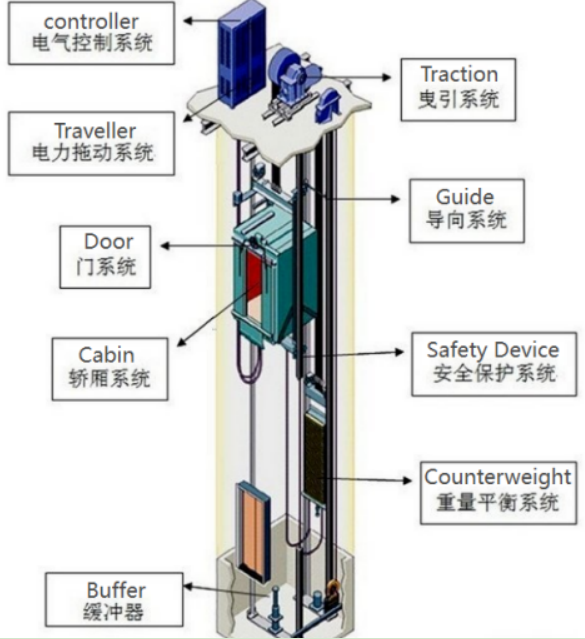

3. Safety Devices

Passenger elevators have comprehensive safety features, including emergency brakes, overload alarms, anti-pinch devices, emergency lighting, and communication systems, ensuring passenger safety in case of malfunctions. While freight elevators also have safety measures, they are primarily designed for cargo transport and cannot provide the same comprehensive safety guarantees as passenger elevators.

Potential dangers of freight elevators transporting passengers

1. Lack of emergency rescue facilities

Freight elevators are usually not equipped with emergency call buttons or emergency telephones or other rescue facilities. If passengers encounter a malfunction while riding a freight elevator, it will be difficult for them to send out a distress signal in time, leading to a delay in rescue and increasing the danger to those trapped.

2. Poor cabin environment

Freight elevators typically have poor ventilation and lighting conditions, and being trapped in such an environment for an extended period of time may negatively impact a passenger’s health.

3. Insufficient safety devices

The anti-pinch devices on freight elevators are not sensitive enough to body movements, making it easy for people to be pinched when entering or exiting. Their overload protection devices have low sensitivity to the weight of people, making it difficult to accurately determine if the elevator is overloaded. When there are many passengers or heavy loads, they may not be able to issue an alarm in time, leading to elevator malfunctions.

Potential dangers of passenger elevators transporting goods

1. Wear and damage

Moving goods can easily wear down the walls and floors of passenger elevator cars. Especially when transporting building materials such as sand, concrete, and tiles,these materials may fall and stick to the elevator’s transmission and running parts through gaps, causing wear and tear on the parts, increasing the failure rate, and affecting elevator operation.

2. Overloading risk

Passenger elevators have limited load-bearing capacity. Overloading can easily damage the load-bearing system, and may also cause wear and tear on the wire ropes, brake failure, and lead to safety accidents.

3. Eccentric load danger

If the weight of goods is not properly distributed in the passenger elevator car, it can easily lead to uneven loading. This will affect the elevator’s operational balance, increase the risk of elevator malfunction, and cause the elevator to tilt or become uncontrollable, endangering the safety of passengers and goods.

Post time: Jan-09-2026