Wholesale Elevator Brackets from Trusted Suppliers – Quality & Value

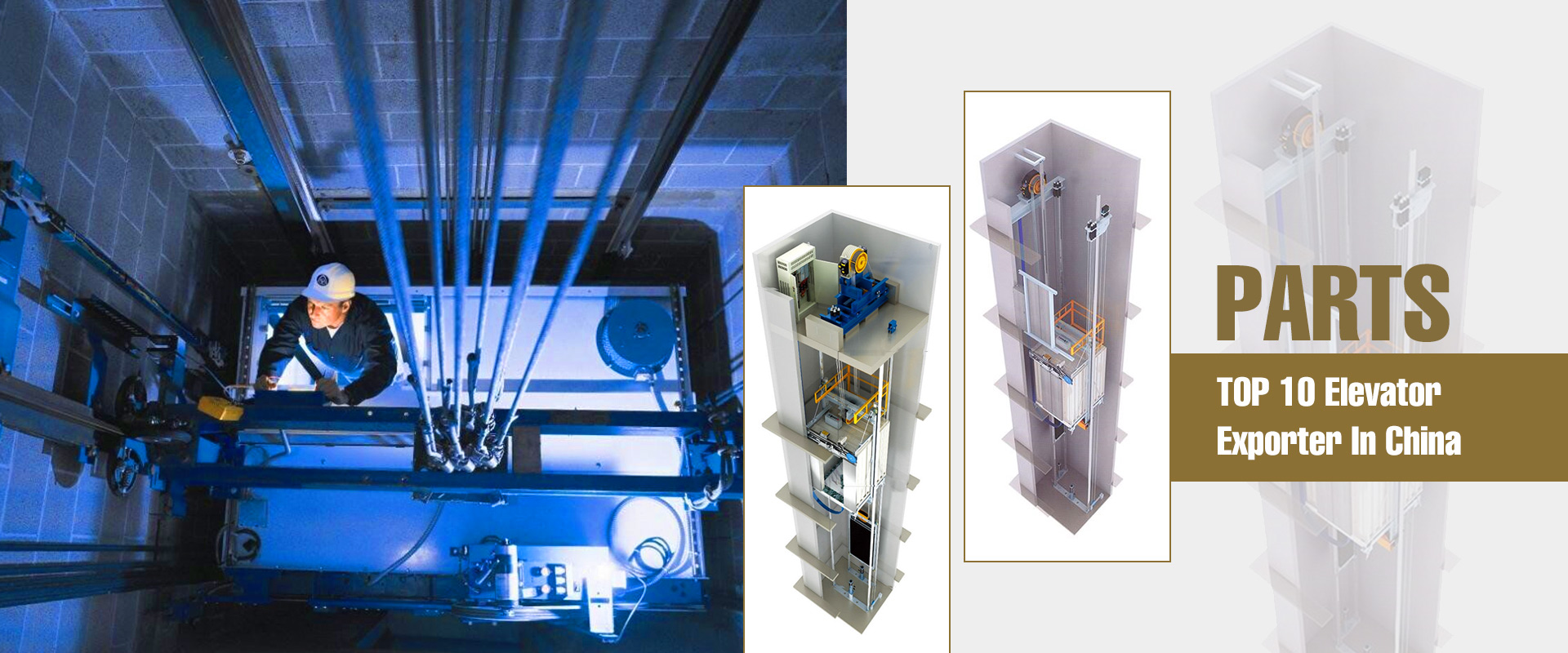

When I first came across the Elevator Bracket, I knew it was a game-changer for businesses in the industry. These high-quality brackets are essential for ensuring the stability and safety of elevator systems, and when purchased wholesale, they become a cost-effective solution for suppliers looking to boost their inventory without breaking the bank. I found that the durability and strength of the Elevator Bracket are impressive, making them the perfect choice for both new installations and replacements. For B2B purchasers, sourcing these brackets in bulk not only streamlines operations but also enhances overall project efficiency. The reliable supply from trusted manufacturers assures me that I’m getting the best products available, which is crucial when dealing with heavy machinery. If you’re a supplier seeking to expand your offerings, these Elevator Brackets should definitely be on your radar! You won’t regret investing in such essential components for your business.

Elevator Bracket Sets the Industry Standard Exceeds Industry Benchmarks

In an ever-evolving industrial landscape, the importance of quality and performance cannot be overstated. The latest innovations in elevator bracket sets are setting new industry standards that not only meet but exceed existing benchmarks. These advancements come in response to the growing demands for safety, reliability, and efficiency in vertical transportation systems. As a global procurement professional, recognizing the impact of high-quality components like elevator brackets is crucial for optimizing operational performance and ensuring the longevity of your investments. The superior design and materials used in the latest elevator bracket sets contribute significantly to their enhanced durability and load-carrying capabilities. Rigorous testing and adherence to international safety regulations ensure these products provide peace of mind while delivering outstanding performance. By integrating cutting-edge technology with meticulous engineering, these bracket sets serve as a cornerstone for modern elevator systems, assuring buyers of their value and long-term benefits. Furthermore, the commitment to continuous improvement and innovation in the manufacturing process not only sets a new benchmark but also enhances the overall effectiveness of elevator installations. As global procurement managers look to make informed decisions, understanding the advantages of adopting these industry-leading bracket sets can drive significant operational efficiencies and reduce maintenance costs. Elevate your projects with confidence, knowing that choosing premium elevator components translates directly to enhanced safety and reliability in vertical transport solutions.

Elevator Bracket Sets the Industry Standard Exceeds Industry Benchmarks

| Dimension | Standard Value | Exceeded Value | Comments |

|---|---|---|---|

| Load Capacity (kg) | 1500 | 1800 | Higher load capacity enhances safety. |

| Cycle Life (cycles) | 5000 | 7000 | Longer cycle life ensures durability. |

| Temperature Resistance (°C) | -10 to 50 | -20 to 60 | Wider temperature range for versatile applications. |

| Weight (kg) | 30 | 25 | Lighter weight for easier installation. |

| Corrosion Resistance | Standard | Advanced | Improved resistance extends service life. |

Related Products