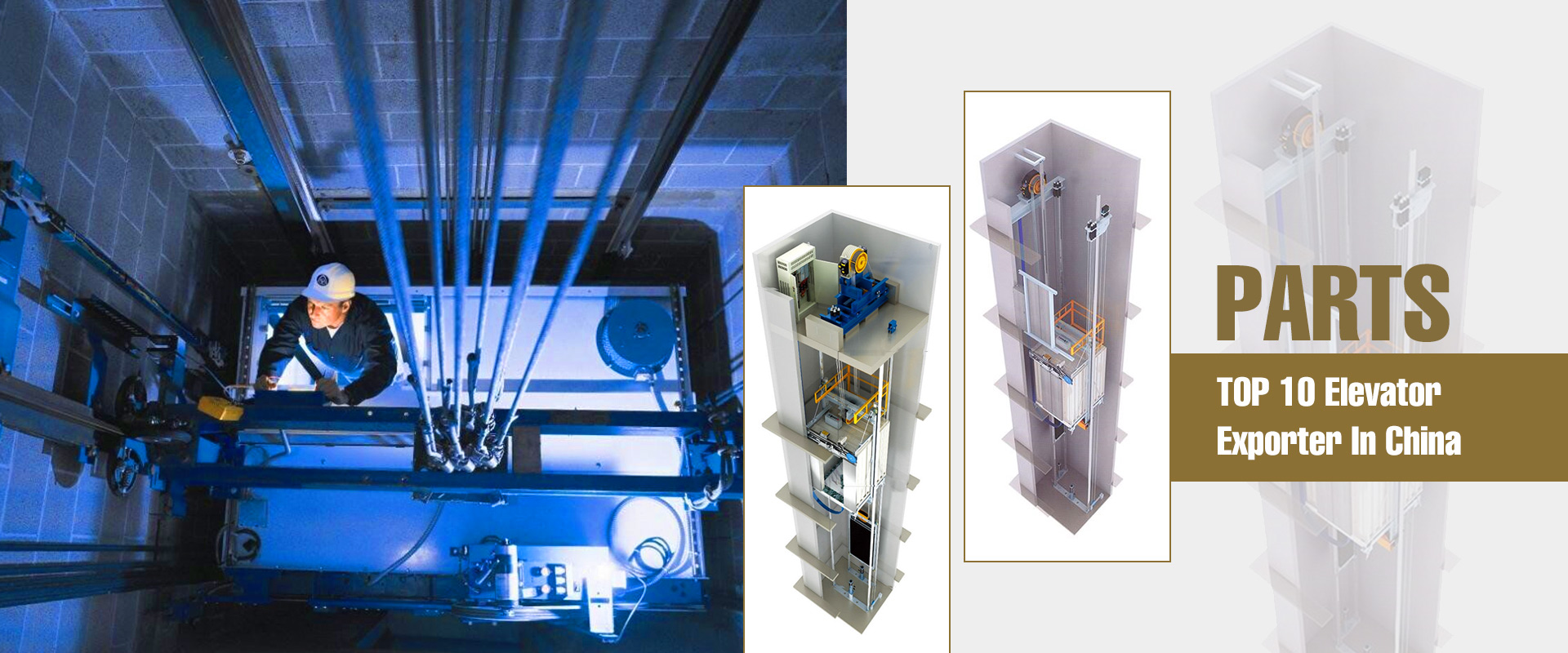

Wholesale Sheave in Elevator: Top Suppliers for Quality Solutions

When it comes to sourcing top-quality sheaves for elevators, I understand the importance of durability and reliability. That’s why I partner with trusted wholesale suppliers who provide exceptional products tailored for the elevator industry. Our sheaves are designed to enhance performance, ensuring smooth and efficient operation in any vertical transport system. With a wide range of sizes and materials available, I can help you find the perfect sheave to meet your specific needs. Whether you're looking for a standard model or something customized, I’m here to assist you every step of the way. I can assure you that our sheaves undergo rigorous testing to meet the highest safety standards, making them a smart investment for any business. Let's connect to discuss how our sheaves can elevate your operations and contribute to your success in the industry. Quality and efficiency are just a conversation away!

Sheave In Elevator Products Winning in 2025

As the elevator industry evolves rapidly, the importance of durable and efficient sheaves cannot be overstated. By 2025, the demand for high-quality sheave products will escalate, driven by advancements in technology and the increasing focus on energy efficiency. Manufacturers are now innovating to create sheaves that not only support the functionality of elevators but also reduce operational costs. These advances will lead to significant improvements in performance, longevity, and sustainability, attracting global buyers who prioritize quality and reliability in their procurement processes. Key trends shaping the sheave market include the integration of materials science advancements and enhanced design methodologies. Innovations such as lightweight composite materials and precision-engineered profiles ensure that sheaves achieve optimal performance while minimizing wear and tear. This shift towards sustainable products is also crucial as regulatory frameworks increasingly favor environmentally friendly solutions. Global purchasers are encouraged to stay ahead by aligning their sourcing strategies with these emerging trends, securing partnerships with forward-thinking suppliers who prioritize innovation and quality. As we look to the future, the competitive landscape for sheave products will hinge on adaptability and collaboration within the supply chain. Companies that invest in research, development, and strategic alliances will position themselves as leaders in the marketplace. With a proactive approach to identifying and procuring cutting-edge sheave products, global buyers can ensure that they are equipped to meet the rising demands of 2025 and beyond, ultimately enhancing their operational efficiency and brand reputation within the industry.

Sheave In Elevator Products Winning in 2025

| Product Type | Material | Diameter (mm) | Weight (kg) | Load Capacity (kg) | Market Share (%) |

|---|---|---|---|---|---|

| Standard Sheave | Steel | 100 | 12 | 5000 | 25 |

| Lightweight Sheave | Aluminum | 75 | 8 | 3000 | 18 |

| Heavy-duty Sheave | Composite | 120 | 15 | 8000 | 30 |

| Compact Sheave | Plastic | 50 | 5 | 2000 | 12 |

| Safety Sheave | Steel | 90 | 10 | 4000 | 20 |

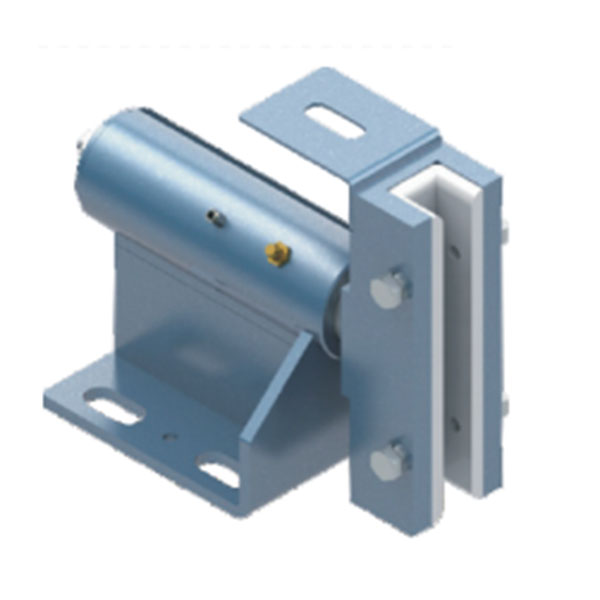

Related Products