OEM Factory for Single Door Elevator - 2-Leafs Center Opening Permanent Magnet Synchronous Door Operator THY-DO-100A – Tianhongyi

OEM Factory for Single Door Elevator - 2-Leafs Center Opening Permanent Magnet Synchronous Door Operator THY-DO-100A – Tianhongyi Detail:

1.Fast Delivery

2.The transaction is just the beginning, the service never ends

3.Type: Door Operator THY-DO-100A

4.We can provide synchronous and asynchronous door operator systems of BST,NBSL,OULING, ES,YS, HD and other brands.

5.Trust is happiness! I will never fail your trust!

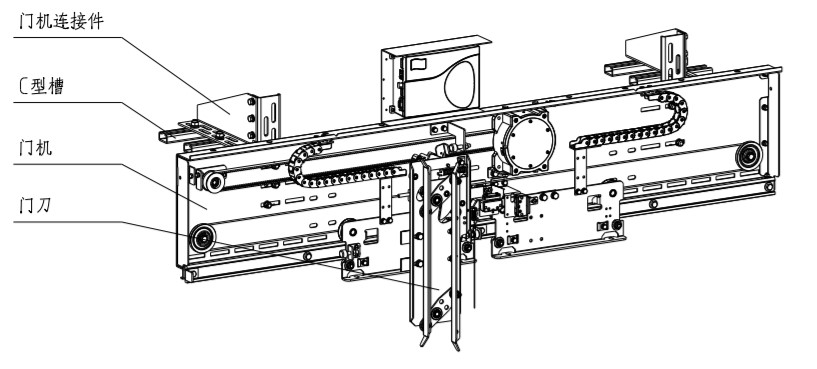

1. The door machine adopts synchronous belt transmission. The synchronous belt is optimized for vibration and noise reduction. The synchronous belt wheel is made of wear-resistant material, which has lower operating noise and longer service life of the synchronous belt.

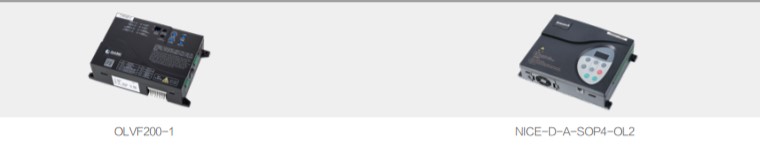

2. Adopting domestic and international well-known brand elevator door machine special frequency converter, closed-loop vector control technology. With the direct drive of the permanent magnet synchronous motor, there are fewer transmission devices, more reliable operation, less loss, more environmental protection and energy saving, and higher control accuracy.

3. The door knife adopts a synchronous door knife and comes with an integrated car door lock. There is no need to install a bumper on the floor door device layer by layer, which truly realizes the synchronous opening and closing of the hall door and the car door. Rolling bearings are embedded in each rotating part and connected with the pin shaft. The door knife retracts and releases the knife flexibly, without sliding friction, no wear, and maintenance-free. The transmission mechanism is cushioned by rubber, and it runs reliably without mechanical noise.

4. The door machine installation method can be divided into straight beam installation, car top installation and front wall installation. The most suitable installation method can be selected according to the different structure of the car designed by the customer. During installation, the door machine can realize three-dimensional adjustment, which is convenient, simple and reasonable. The door hanging plate is equipped with a safety hook to prevent impact and fall off, which is safe and reliable.

Car top installation brackets

Strengthened installation bracket

Fixing pipe for car top installation(optional)

1. Fix the door machine connector on the C-shaped groove of the car top and pre-tighten with 4 fixing parts; then fix the door machine on the door machine connector and pre-tighten with 6 M8*20 square neck bolt groups.

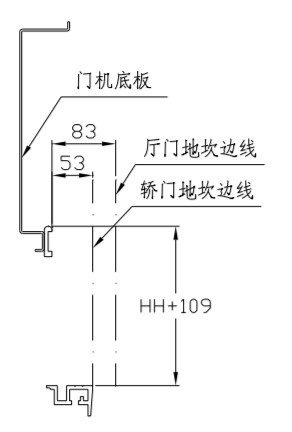

2. Adjust the height and left and right dimensions of the door machine: adjust the distance between the top surface of the guide rail and the car door sill to HH+109mm (HH is the door opening height) through the long hole on the door machine connector; adjust through the long hole on the door machine The deviation between the door machine center and the door opening center is ±1mm (see picture).

3.Adjust the verticality of the door machine bottom plate: adjust the verticality of the door machine bottom plate to ± 0.5mm by laying the vertical line or taking the landing door sill as the reference. You can adjust the door machine connector connecting bolts or the door machine connector Add shims to the C-slot for adjustment.

4. Adjust the distance and parallelism between the door machine guide rail and the sill: Using the landing door sill as the benchmark, adjust the distance from the end of the door machine guide rail to the landing door sill to 83, and the distance between the two ends of the door machine guide rail and the landing door sill equal.

5. After reviewing the following main parameters of the door machine installation, tighten all the door machine bolts:

•Door machine height: the distance between the top surface of the door machine guide rail and the car door sill is HH+109mm;

•Door machine center: the deviation between the door machine center and the door opening center is ±1mm;

•The distance between the door guide rail and the landing door sill: The distance between the door guide rail and the landing door sill is 83mm.

Product detail pictures:

Related Product Guide:

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for OEM Factory for Single Door Elevator - 2-Leafs Center Opening Permanent Magnet Synchronous Door Operator THY-DO-100A – Tianhongyi , The product will supply to all over the world, such as: Ireland, Cannes, Lahore, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly