Personlized Products Traction Sheave Elevator - Asynchronous Geared Elevator Traction Machine THY-TM-YJ150 – Tianhongyi

Personlized Products Traction Sheave Elevator - Asynchronous Geared Elevator Traction Machine THY-TM-YJ150 – Tianhongyi Detail:

| Suspension | 1:1 |

| Max.Static Load | 3500kg |

| Control | VVVF |

| DZE-9EA Brake | DC110V 1.5A |

| Weight | 310kg |

1.Fast Delivery

2.The transaction is just the beginning, the service never ends

3.Type:Traction Machine THY-TM-YJ150

4.We can provide synchronous and asynchronous traction machines of TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG and other brands.

5.Trust is happiness! I will never fail your trust!

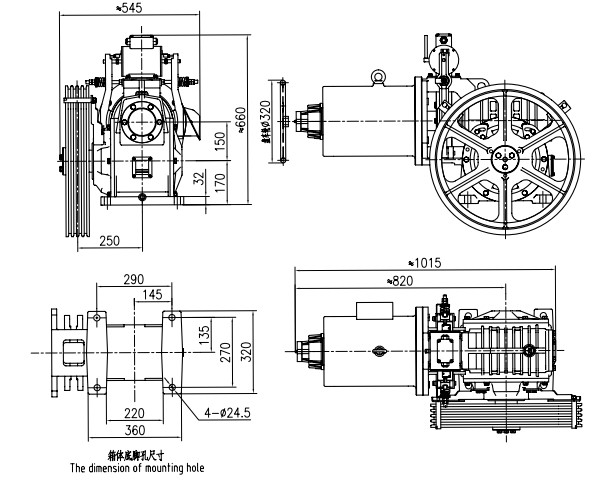

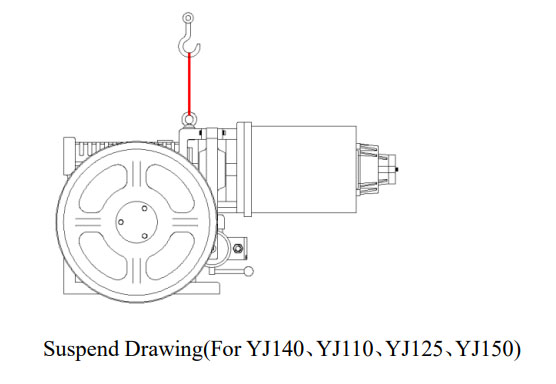

THY-TM-YJ150 geared asynchronous elevator traction machine complies with TSG T7007-2016, GB 7588-2003, EN 81-20:2014 Safety rules for the construction and installation of lifts -Lifts for the transport of persons and goods -Part 20 : Passenger and goods passenger lifts, EN 81-50:2014 Safety rules for the construction and installation of lifts -Examinations and tests -Part 50: Design rules, calculations, examinations and tests of lift components. The brake model corresponding to the traction machine is DZE-9EA. It is suitable for freight elevator with a load capacity of 500KG~750KG. It adopts a worm gear reducer type. The worm material is 40Cr and the worm wheel material is ZQSn12-2. The machine is right-mounted and left-mounted is available.The lubricant grade we recommend is Shell Omala S2 G460 or lubricant of corresponding viscosity grade, YJ150 (motor ≥10KW) filled with 460 synthetic oil. The traction machine is equipped with a mechanical manual brake release device, which is used to manually move the car when the elevator fails. It is strictly prohibited to use it in non-emergency situations. Suitable for indoor working environment.

1. Set the brake release wrench to the brake;

2. Turn the brake release wrench in any direction to release the brake.

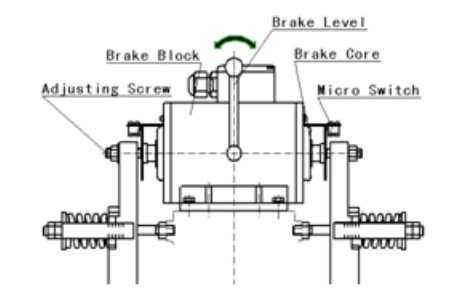

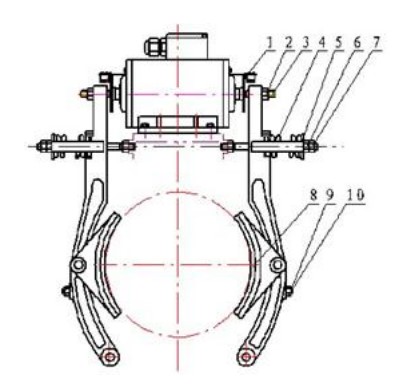

1. Adjustment of braking force: Loosen the nut 6 and the nut 7 on the main spring end to make the spring in a free state, pull the nut 6 to make the spring cap 5 abut against the free end of the spring, receive a slight force, and turn the nut clockwise 6 Obtain sufficient braking force, and then tighten with nut 7.

2. Adjustment of the brake shoe: the brake system is in the state of holding brake. When the pressure spring generates enough pressure to compress the brake arm, the arc surface of the brake shoe is close to the arc surface of the brake wheel. At this time, adjust the lower end of the brake shoe. 9 of the screw so that the screw is just on the lower end of the brake shoe. When the brake is energized to release the brake, turn the screw 9 counterclockwise, and use a feeler gauge to measure the gap between the brake shoe and the two curved surfaces of the brake wheel. When the gap is adjusted to be basically even up and down, use the nut 10 to lock the screw.

3. Adjustment of the brake opening gap: loosen the nut 2, energize the brake, measure the gap between the brake shoe 8 and the two arc surfaces of the brake wheel with a feeler gauge after opening the brake, and ensure that the gap between the brake shoe and the two arc surfaces of the brake wheel is 0.1- 0.2mm (in principle, it is advisable to ensure that there is no friction between the brake shoe and the brake wheel when opening the brake). When the opening gap is too small, the screw 3 should be turned clockwise to reduce the gap between the screw 3 and the striker cap, and vice versa to increase the gap. When adjusted to a proper position, use nut 2 to lock screw 3 tightly. Recheck whether the idle stroke of the brake meets the requirements.

4. Adjustment of brake opening synchronization: turn on and off the brake power and observe the speed synchronization of the brake arm when opening the brake. When one side is faster and the other side is slow, if the braking torque is sufficient, the slower end will shorten the brake action Stroke (loose the screw), on the contrary, the faster end increases the brake stroke (tighten the screw). Adjust while observing, and lock the nut until it is synchronized. Recheck whether the idle stroke of the brake meets the requirements. After the adjustment, check whether the interconnected and locked parts are locked, and perform a braking force test or elevator static load test.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Personlized Products Traction Sheave Elevator - Asynchronous Geared Elevator Traction Machine THY-TM-YJ150 – Tianhongyi , The product will supply to all over the world, such as: Surabaya, Mauritius, Salt Lake City, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!